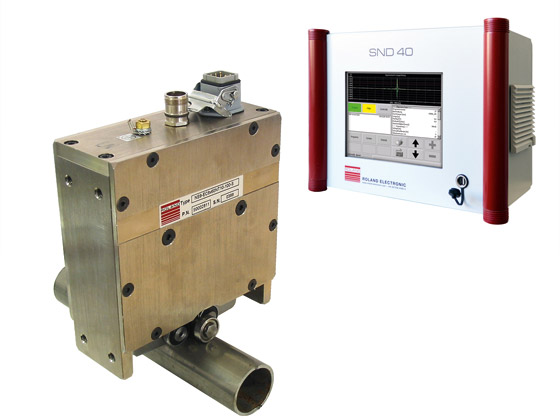

SND40 offers a maximum of flexibility in Weld Seam Detection. The great benefit lies in the combination of magnetic flux leakage and eddy current technology; the customer can process all sort of metals and can expect even at cold drawn or heat treated materials a remarkable reliability. The system is able to process tube diameters from 5 to 1000 mm (0.19 to 39.37 in) at a wall thickness up to 12.5 mm (0.49 in).

Applications

The new SND40 system is the first PC based system of its kind. It combines the strengths of analog sensor principles with digital signal analysis for the purpose of weld seam detection. For many years tried and proven magnetic leakage flux sensors and new types of eddy current probes make the SND40 a highly flexible weld seam detection system.

Features

control unit via touchscreen adjustable

large display of sensor signals and analysis

optional use of mouse/keyboard

printer connection available

storage of 31 measurement programs